3D Printing: It's the future! (Well... it's really the past)

3D printing introduction post to this blog.

When we show the 3D printers at the fabLAB to those who visit us, it’s common to hear expressions like the one that gives the title to this post: “It’s a revolution!”, “This is the future!”, “Of course!, in a few years we are all going to have one at home, right?”.

Depending on how much time we have for the visit and the nature of it, we explain that this is not exactly like that, first, 1990 it’s not the future, it’s the past, and we should remember that 1990 was not 10 years ago, it’s more like a quarter of a century ago, the year the company Stratasys started to sell their first FDM (Fused Deposition Modeling) printers, which is the technology used by all printers here at fabLAB Asturias, both the Makerbot Thing-O-Matic and all the RepRap project printers.

The key to understand what’s really happening with 3D printing is on the patents. S. Scott Crump patented FDM technology back in 1989, and when did MakerBot start their activity? Exactly 20 years later, what a coincidence! That's the precise moment when everyone could freely design and build their own 3D printers (no royalties for you, Mr Scott). And that’s exactly what happened, organized through the internet and the growing Open Software/Hardware community, RepRap started their project started in 2005 and later on, companies like Makerbot and Ultimaker intorduced these machines (now open source) in the market.

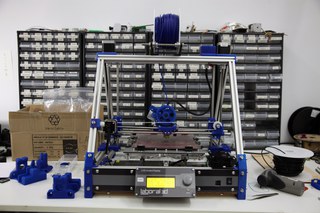

The purpose of this post is not to give a history class on 3D printing, but to introduce the relation of 3d printing and fabLAB Asturias. And as at any other Fab Lab, this relation starts from the very beginning, every Fab Lab has a 3D printer, all kind of technologies and sizes, but there’s always one. Here at fabLAB, the first printer was a Makerbot Thing-O-Matic.

The most important characteristic of 3D printers, compare to other machines at a Fab Lab is their price. Nowadays, 3D printers kits for assembly start at 300 euros, that makes 3D printing affordable for hobbyists and professionals that find in this machine a very useful tool for the development of their projects. It´s with that idea in mind, we’ve been investigating and using these machines as a resource for artistic projects as well as for purely technical uses, here at fabLAB ASturias.

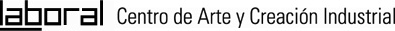

In June 2013, Eduardo Marcos García, a user of fabLAB Asturias, proposed a collaboration for developing and building a 3D printer, he needed both to use the printer at fabLAB and our technical support. The answer was definitive: “count on us!”. First week September 2013, we were already making the first printing tests on the first prototype, how was it possible to design and build a 3D printer in 3 months? Well, we didn’t. The design base started with a model from RepRapBCN, at the same time based on the RepRap MendelMax. The thing is: unless we wanted to make a completely new machine with a different concept of operation (i.e. Rostock model), not to use their work would have been a lack of respect to the prior efforts of hundreds of people who also share their designs. On the other hand, it wouldn't be very smart not to use the time and the resources available to design something exactly the same instead of taking a fully functional design and focus our efforts on improving it. And that is exactly the real future! Not the technology that allow us to control how we deposit fused plastic, but the mechanisms in society that gather hundreds, maybe thousands of people to work and share their knowledge in a collaborative project.

A couple of weeks ago, January 28th 2014, the patent for the 3D printing technology known as SLS (Selective Laser Sintering) expired, even being a more advanced technology than FDM, it´s still not the future, we are talking about a 20 years old technology; the future is the community that a couple of years ago marked that date in their calendars and started preparing designs for new machines with SLS (now property of everyone) and making them available maybe not to everyone, but to more and more people.

What stage has the 3D printer reached at fabLAB Asturias? At the moment, we have an open registration for a workshop on 3D printers assembly that includes a kit to build a printer and a four day course to learn how to assembly, adjust and print the machine This workshop will be given by Eduardo Marcos García and the fabLAB team. Furthermore, Eduardo keeps investigating on modifications to add to the design we are currently working with, redesigning the whole structure so it takes less time to get all the pieces. You can follow developments and achievements of this whole project in this blog.